THE RAW PRODUCT BEFORE SHAPING

The propeller has been glued and in the press bed for hours, ready to be carved and shaped

Click the photo to enlarge. (Best viewed on a computer or tablet)

Tiger Moth prop fresh out of the press bed and with it's hub holes bored

This rudimentary prop shape is now ready for round one of carving!

Hub holes bored, this one is also ready for carving! (Tiger Moth prop - Jeff had 4 of them on the go at once)

Different angle of the previous Tiger Moth prop

Showing the "fanned out" boards all glued together, ready for carving

2x Sopwith Scout propeller blanks, ready for carving

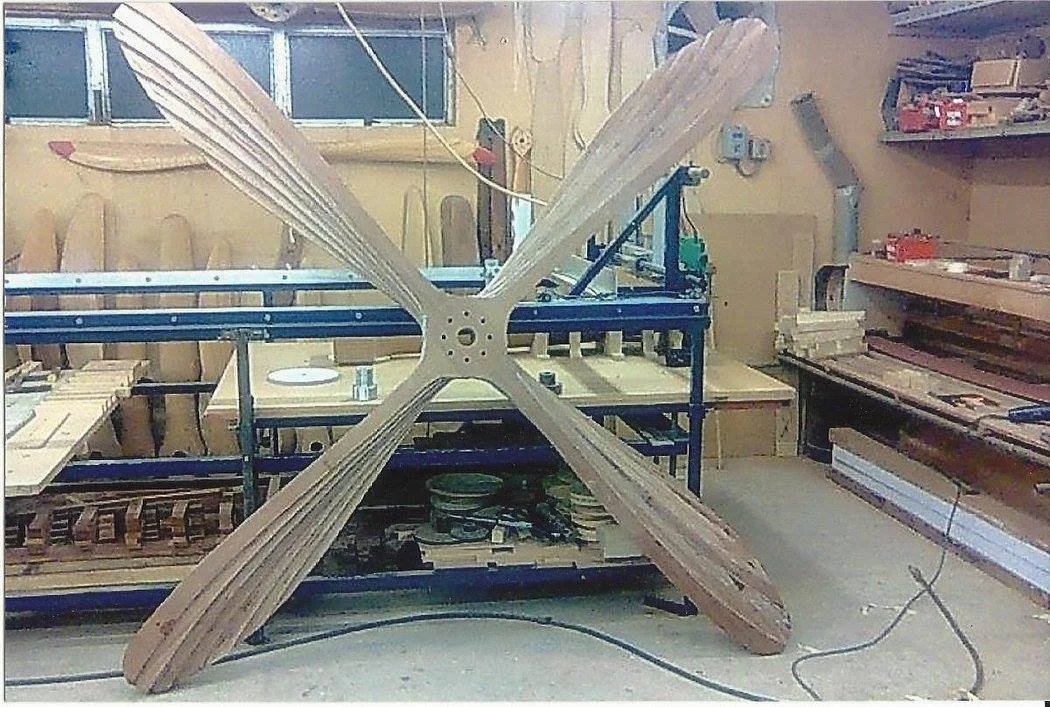

A 4-bladed RE8/ BE12 propeller ready for carving

A 4-bladed RE8/ BE12 propeller getting track-checked

A 4-bladed RE8/ BE12 propeller ready for machining

Making sure the fanned-out boards will fit into place before gluing

Test propeller for CAMS about to be glued up

After gluing, before carving

The bolt holes have been bored on the hub of this prop for a Gypsy Moth. Ready for carving now!

The backside of the hub of a Gypsy Moth prop, freshly bored

Gypsy Moth propeller ready for carving and shaping!

CLICK HERE TO GO BACK TO THE MAIN GALLERY TO VIEW EVEN MORE PHOTOS!